CUHK

News Centre

CUHK develops a new squirting cucumber-inspired mechanism that significantly enhances the power output and mobility performance of miniature robots

The use of miniature robots is becoming more widespread, but developing highly efficient actuation systems that fit into them to enhance their mobility remains a substantial challenge for the industry. A research team in the Department of Mechanical and Automation Engineering at The Chinese University of Hong Kong (CUHK) has drawn inspiration from the seed dispersal of the squirting cucumber to pioneer a technology that significantly boosts the power output of miniature robots – accumulated strain energy-fracture power amplification mechanism (ASEF).

CUHK has actualised ASEF in a light-driven hydrogel launcher that surpasses current conventional micro-engineered systems in terms of power output and motion performance. The new power amplification mechanism has great potential to increase the power output of miniature robots, expanding their application, including the development of medical robots capable of deep tissue sampling inside human bodies without invasive procedures. Study results have been published in the international academic journal Nature Materials.

Research team breaks through technological bottleneck with plant-inspired innovation

Miniature robots, about the size of insects, can perform tasks in confined spaces that are challenging for traditional large-scale instruments, such as going into human bodies to take clinical samples. However, due to their tiny size, miniature robots have very limited capacity to carry energy resources and components. Therefore, new technologies are required to enable them to accumulate and release energy instantaneously, amplifying their power.

During the growth of Ecballium elaterium, the squirting cucumber, its pulp transforms into mucilaginous liquid mass, causing the fruit wall to stretch significantly under pressure. The elastic energy accumulates until the critical pressure is reached, resulting in a fracture that ejects seeds over a considerable distance, at high velocity and acceleration.

The CUHK research team has used this as inspiration to tackle the technical bottleneck in powering miniature robots. With theoretical and methodological advice from Zhejiang University and Carnegie Mellon University in the US, the research team developed ASEF and actualised it with a light-driven hydrogel launcher. The launcher is fabricated of hydrogel material of high toughness and stretchability, which is doped with graphene to give it excellent photothermal conversion ability. When the launcher is irradiated with near-infrared light, the graphene heats up rapidly, causing water vaporisation and volume expansion. That deforms the hydrogel network and stores substantial strain energy, a term referring to the energy produced during the deformation process. Once the energy stored reaches its limit, the bottom of the launcher fractures, releasing the accumulated elastic energy within 0.3 milliseconds (ms) as the strain energy is instantaneously converted to kinetic energy.

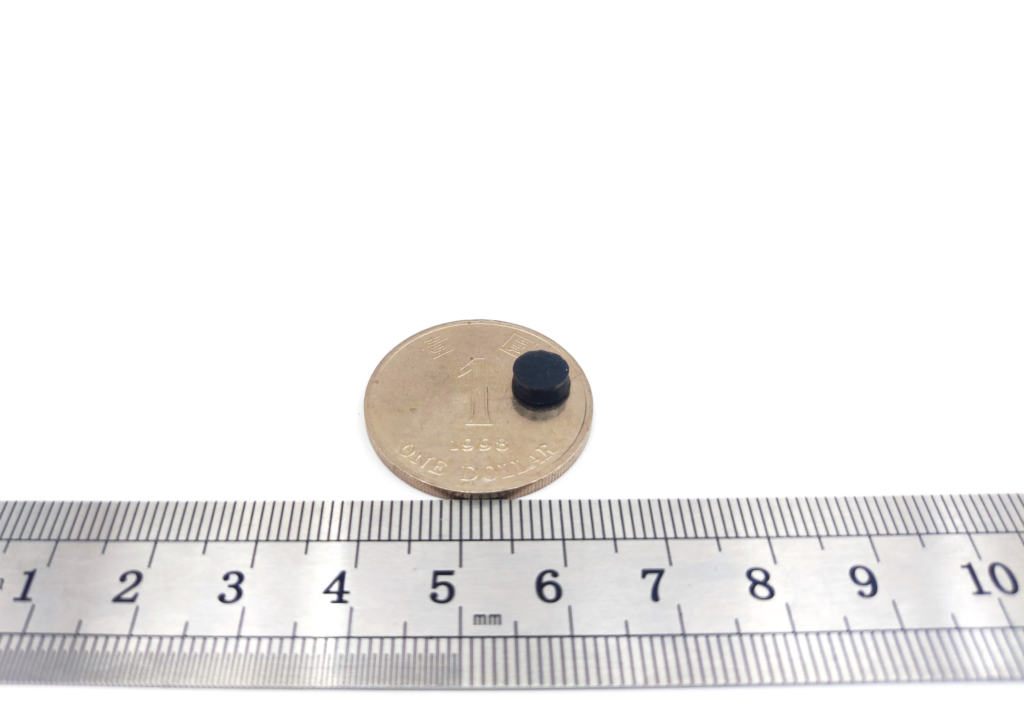

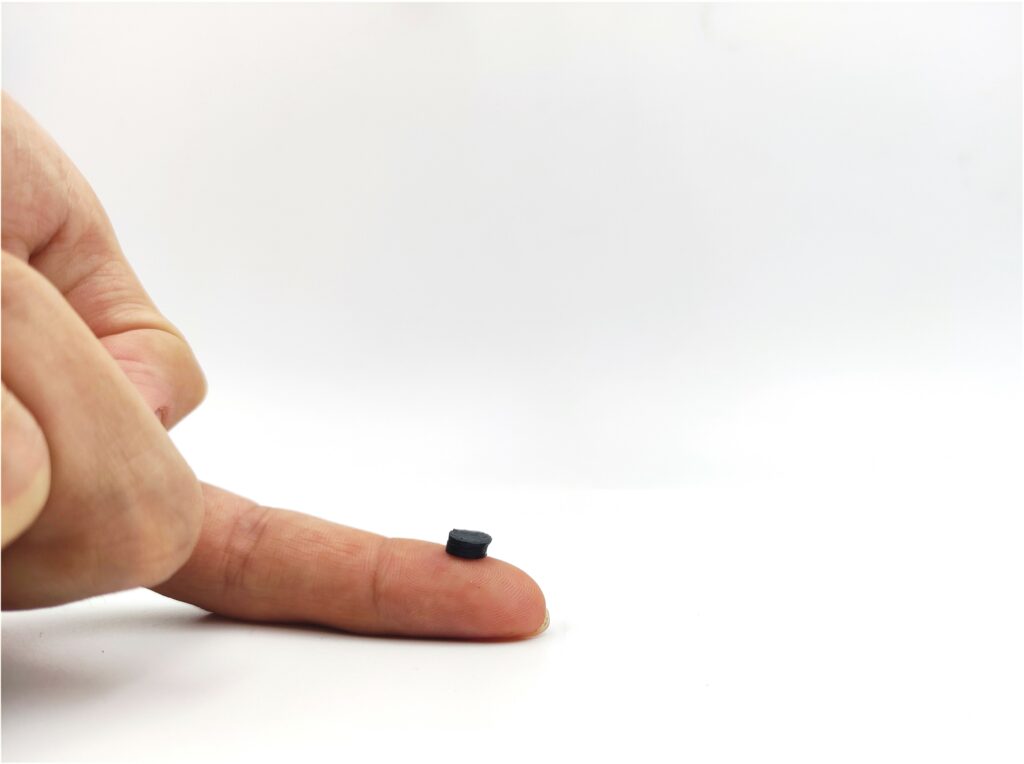

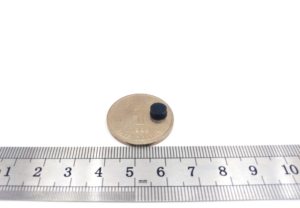

A hydrogel launcher based on the ASEF actuation with a diameter of 7 mm and thickness of 3 mm – comparable in size to a button cell battery – can achieve a vertical launch height of over 193 cm, equivalent to 643 times the body length of the launcher; a take-off velocity of approximately 7.5 m/s (27 km/h); and acceleration of 25,000 m/s², or 2,500 times the acceleration of gravity. The performance of the light-driven ASEF-based hydrogel launcher surpasses current conventional micro-engineered systems in terms of power output and motion performance.

Professor Zhang Li from the Department of Mechanical and Automation Engineering at CUHK, who led the research, explained, “Take archery as an example. When the finger pulls back on the bowstring, it gradually accumulates energy. Upon release, a large amount of energy is instantly discharged, amplifying the power.”

He continued, “The ASEF-based hydrogel launcher does not involve complex structures in its design or complicated fabrication process; it can be made from many different materials at low cost. Currently, each hydrogel launcher can only be used once due to the bottom fracture after launching. We are exploring hydrogel material systems that can heal themselves, so they can be used repeatedly.”

Professor Zhang further stated, “We envision that this new mechanism can replace existing actuating components within miniature robots, significantly enhancing their power output. This could enable them to perform tasks such as stent delivery, tissue sampling and excision within deep tissues like the intestines, benefiting more patients. In the agricultural field, a light-driven hydrogel launcher could allow robots to have sufficient driving and output capability to carry seeds and RFID tags, and eject them in distant places. In conjunction with RFID reader installed in farmland can achieve the timed water supply. By absorbing water and swelling, the hydrogel material of the robot would release the loaded seed to realise the automatic seeding. Moreover, the exceptional mobility performance based on this new actuation mechanism, holds promise as a novel propulsion method for exploration robots in the gravity-free or microgravity environment of the Moon or Outer space.”

Acknowledgment

The research is supported by the Research Grants Council (RGC), the Croucher Foundation, the Multi-scale Medical Robotics Centre (MRC), the SIAT-CUHK Joint Laboratory of Robotics and Intelligent Systems and the CUHK T Stone Robotics Institute.

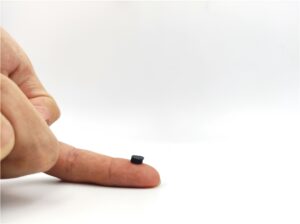

CUHK has led the development of a novel light-driven ASEF-based hydrogel launcher (pictured), only a few millimetres in size, with mobility performance significantly surpassing that of launchers that use traditional techniques. This innovation holds promise for enhancing the performance of miniature medical robots.

CUHK has led the development of a novel light-driven ASEF-based hydrogel launcher (pictured), only a few millimetres in size, with mobility performance significantly surpassing that of launchers that use traditional techniques. This innovation holds promise for enhancing the performance of miniature medical robots.

CUHK has led the development of a novel light-driven ASEF-based hydrogel launcher (pictured), only a few millimetres in size, with mobility performance significantly surpassing that of launchers that use traditional techniques. This innovation holds promise for enhancing the performance of miniature medical robots.