CUHK

News Centre

CUHK develops a 3D-printable bioactive material and other technologies to treat large-to-massive tendon injuries

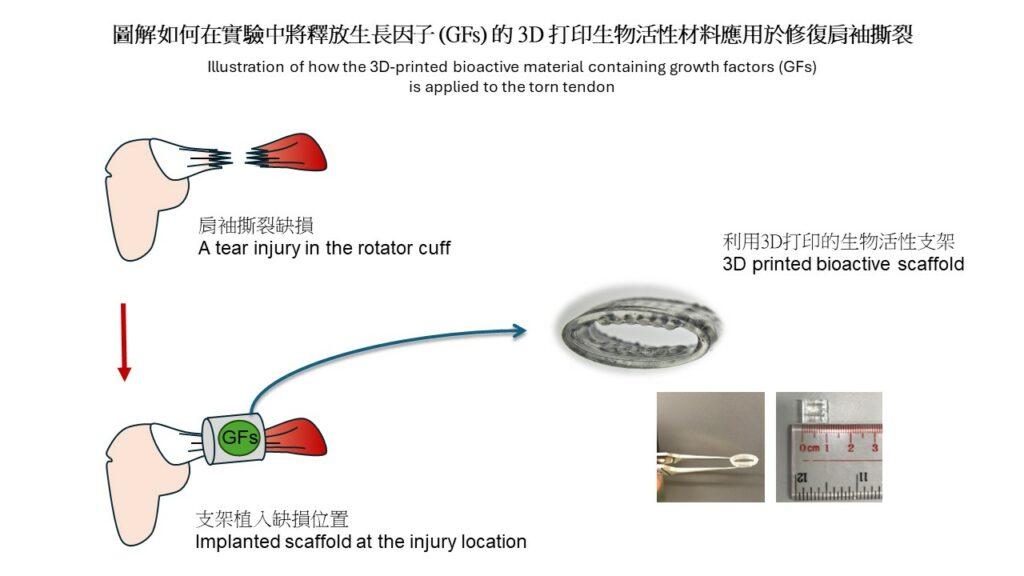

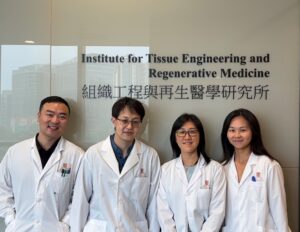

A research team led by Professor Elmer Ker, Assistant Professor in the School of Biomedical Sciences at The Chinese University of Hong Kong (CUHK)’s Faculty of Medicine (CU Medicine), who is also a member of the CUHK’s Institute for Tissue Engineering and Regenerative Medicine, has developed a 3D-printable bioactive material for the repair of severe tears of the shoulder tendons, also known as the rotator cuff. This newly developed material provides adequate mechanical support to sustain normal shoulder movement and with the inclusion of bioactive molecules such as growth factors, is able to enhance tissue regeneration. The fact that it can be 3D-printed not only facilitates economical on-demand fabrication but can also allow the material to be personalised for treating irregular, patient-specific tendon tear shapes. Thus, there is a high potential to apply this invention as a new treatment option in repairing rotator cuff injuries including large-to-massive tears. Details of the research have been published in the international journal Bioactive Materials, with Dr Zhang Xu, a Research Associate (honorary) in Professor Ker’s laboratory, as the first author.

Prevalence of shoulder tendon injuries is expected to rise due to ageing, so more treatment options are needed

Tendon tears, resulting from injuries or tissue degeneration, are common in the general population. For example, the prevalence of shoulder tendon tears is about 20%1. Treatments for shoulder tendon tears depend on the severity of the injury, with large-to-massive injuries typically requiring surgical repair. The prevalence of these tendon injuries is expected to rise dramatically due to the rapidly ageing population.

Injuries of this nature impact all segments of society, including athletes, physical labourers and elderly people, imposing a heavy socioeconomic burden on individuals and society. This includes the financial burden of medical bills and absence from work, occupation-related disability compensation, the inability to attend school or participate in sporting activities, and lower quality of life due to short- or long-term disabilities. This highlights the need for more effective treatment options.

The new material closely mimics natural tendon and promotes at least 1-cm of tendon regeneration

To address these challenges, Professor Elmer Ker’s team has developed a 3D-printable bioactive material that can repair severe rotator cuff injuries. Building on the Nobel prize-winning “click chemistry” technology, a category of chemical reactions that produce high yield with low amounts of undesired side reactions, the team fabricated the 3D-printable tendon biomaterial. This biomaterial possesses highly robust mechanical properties that closely mimic natural tendon, allowing it to be stretched at least 10,000 times without failing. Notably, the team proved that the 3D-printable, tendon-mimicking biomaterial biomechanically restored the shoulder properties of injured rabbits back to healthy levels and delivered bioactive factors to regenerate at least 1 cm of a large tendon injury. As the material can be 3D printed, the manufacturing process is simple and rapid. Additionally, the material can be customised according to the patient’s shoulder structure and the extent and shape of the tear to create personalised graft.

Professor Ker stated, “Our work has achieved the goal of developing an easily manufactured, mechanically robust, pro-regenerative tendon biomaterial that addresses mechanical and biological deficits in rotator cuff injuries while avoiding a complex and laborious production process. We will continue to prove the significant potential of this newly developed material for the repair of large-to-massive rotator cuff injuries, as well as other soft tissue injuries, in a clinical setting.”

In addition, the research team has applied innovative design approaches to optimise bone-tendon repair (published in Acta Biomaterialia in March 2024, with Mr Wang Chen-yang, a PhD student in Professor Ker’s laboratory, as the first author) and developed a pro-regenerative cocktail to promote tendon healing (published in Biomaterials Advances in March 2023, with Dr Li Ke, a post-doctoral fellow (honorary) in Professor Ker’s laboratory, as the first author). Together, the work from Professor Ker’s laboratory addresses the grand challenge of clinically repairing rotator cuff injuries. Patents for several of these technologies have been filed in the United States, Europe and Mainland China.

1 Prevalence and risk factors of a rotator cuff tear in the general population

https://pubmed.ncbi.nlm.nih.gov/19540777/

Professor Elmer Ker (2nd from left), Assistant Professor in the School of Biomedical Sciences at CU Medicine, who is also a member of the CUHK’s Institute for Tissue Engineering and Regenerative Medicine, and his research team members including Mr Wang Chen-yang(1st from left), PhD student; Dr Zhang Xu (2nd from right), Research Associate (honorary); and Dr Li Ke (1st from right), post-doctoral fellow (honorary).