CUHK

News Centre

CUHK Faculty of Engineering Receives the 2018 R&D 100 Award for Developing the Digital Holography-based 3-D Nano-Builder for Ultrafast Micro-/Nano-Prototyping

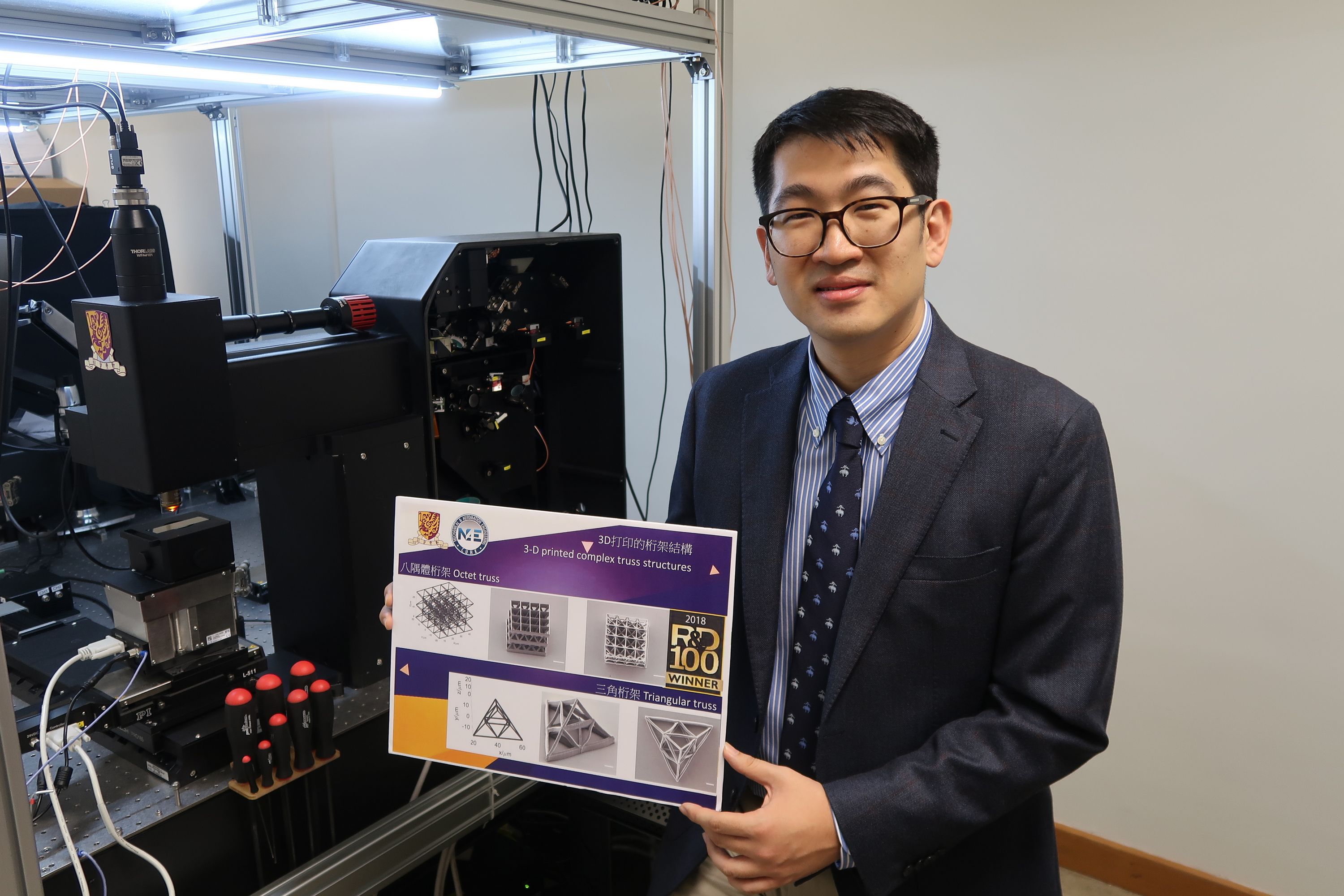

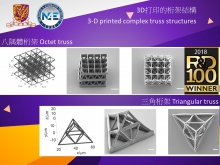

Professor Shih-Chi Chen, Department of Mechanical and Automation Engineering, Faculty of Engineering, The Chinese University of Hong Kong (CUHK) and his team have been honoured with the globally prestigious 2018 R&D 100 Award – “The Oscar of Invention” for the development of the Digital Holography-based 3-D Nano-Builder. It can additively write micro-nano-scale components with complex structures in high speed and is especially suitable for applications in research and development such as printing photonic, robotic, metamaterials, micro-scaffolds, and drug delivery devices.

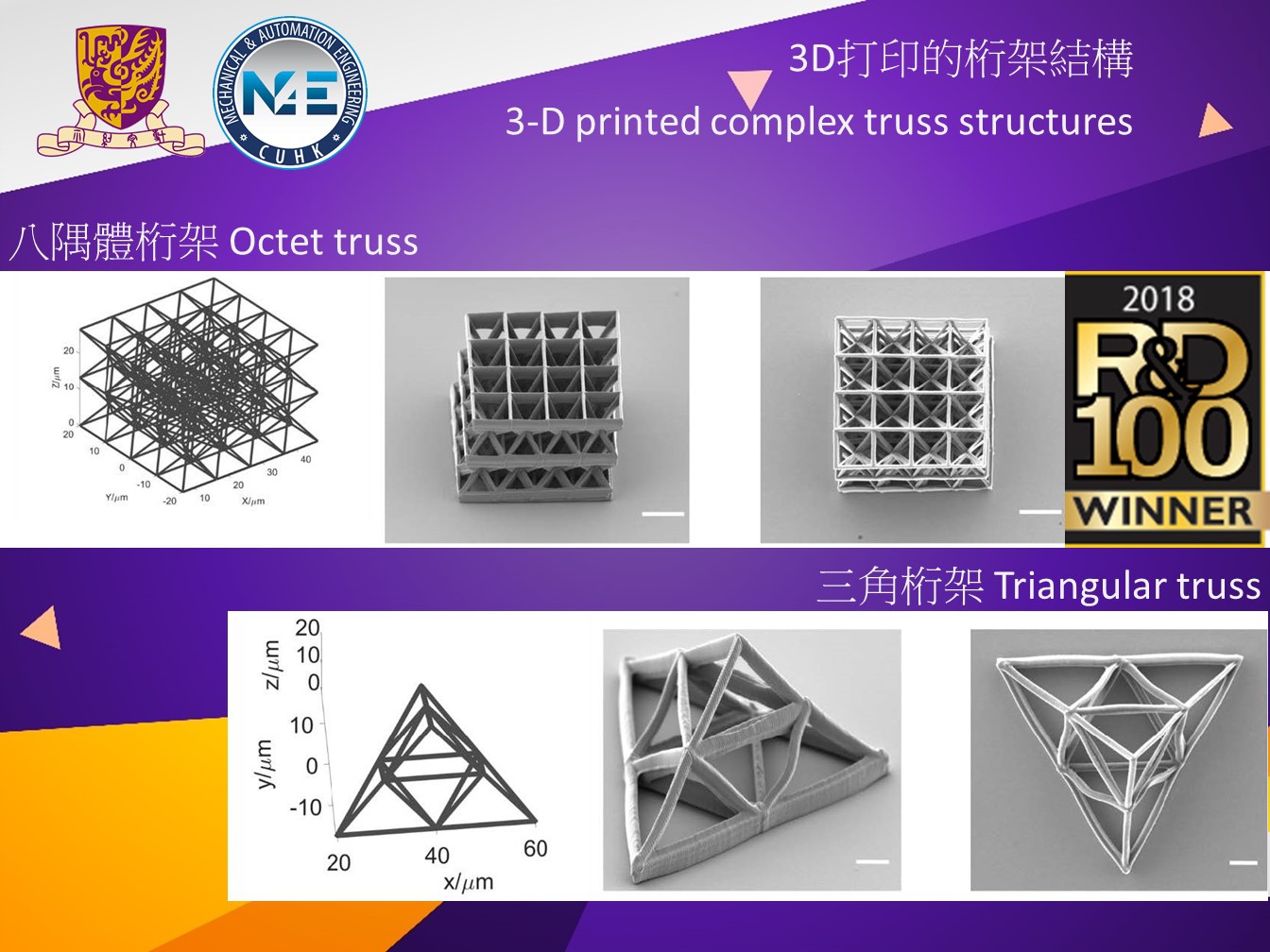

3-D printing technology has generated profound impact on the engineering world and is often considered the technology that drives the third industrial revolution. It covers a broad range of applications such as aviation, medicine, science and technology, and entertainment. 3-D printing has opened new possibilities for various industries by enabling faster and easier prototyping and manufacturing processes, but there are still a number of limitations in speed, resolution and flexibility. The Nano-Builder employs a revolutionary random-access scanning method that allows tens of laser foci to simultaneously write structures at 22.7 kHz. Compared with the existing point-scanning-based systems and solutions, the Nano-Builder presents distinctive advantages in precisely controlling the focus position, and each focal point can be independently controlled to follow any planned trajectory in space, which increases the throughput and reinforces the structure dramatically.

The focal point can be moved to any point in the work space at equal speed. Thus, complex overhanging structures can be printed without supporting structures/materials and the total fabrication time is only proportional to the solid volume of the structure, regardless of the level of complexity. In addition to the efficiency and accuracy, the printing resources can better be utilised, making the entire creation process of 3-D structures more cost-effective. Professor Chen believes the technology can best be applied in creating photonic, microfluidic, biomedical, or mechanical structures or devices and ultimately have impact on the world of manufacturing and micro-/nano-prototyping, accelerating discoveries in science and medicine.

Another distinctive advantage of the Nano-Builder is its modular design and extendibility. By replacing the CCD module with a photomultiplier tube (PMT) module, the Nano-Builder can be easily turned into a high performance two-photon excitation microscope with functions of simultaneous real-time imaging and multi-point optical stimulation—enabled by the holography-based ultrafast multi-focus laser scanner. In the system, femtosecond lasers can precisely stimulate the target cells with submicron precision without affecting the cells around the target, e.g. mouse brains or zebrafish, while simultaneously generating video-rate optical cross-sectional images in vivo.

The CUHK team received funding support from the Innovation and Technology Commission, including multiple tier 2 Innovation and Technology Funds (ITF), as well as the Technology Start-up Support Scheme for Universities (TSSSU) for developing the related laser scanning, imaging, and fabrication technologies over the past few years. The CUHK spin-off company, i.e., Precision Instrument and Optics Limited, from Professor Chen’s group was selected by the Pre-incubation Centre (Pi Centre) of CUHK where the team acquired good resources and support, including consultancies, training, workshops, and networking opportunities with potential investors and mentors.

About R&D 100 Award

The R&D 100 Award was presented to the CUHK team in Orlando, Florida in November 2018. The Awards have long been considered the most globally prestigious recognition of inventions and innovations and are often regarded as the “Oscar of Invention”. The R&D 100 Awards identify and celebrate the top technology products of the year around the world. The winners this year include teams from industry, academia and government institutes such as Leica, ANSYS, Inc., Texas Instruments, MIT, NASA and the US National Renewable Energy Laboratory (NREL). Many important technology breakthroughs that later became household names received the R&D 100 Awards, including the instant colour process film, Polaroid, (1963), the ink-jet printer (1967), the colour copier (1968), lithium batteries (1971), the automated teller machine, ATM, (1973), LCD, (1980), the personal supercomputer (1987), the lab HDTV (1998), and the artificial retina (2009).

Comparisons of 3D Printing Techniques

| Key Features | Current Nanoscale 3-D Printer |

CUHK Nano-Builder |

| Precision 3D printing | Yes | Yes |

| Curing mechanism | 2-photon absorption | 2-photon absorption |

| Coarse fabrication space | 100 × 100 × 3 mm3 | 120 × 120 × 60 mm3 |

| Fine fabrication space (with 40x objective) | 300 × 300 × 300 µm3 | 206 × 103 × 524 µm3 |

| Multi-foci printing | No | Yes |

| Printing process | Layer-by-layer | Arbitrarily, programmable multi-point/ single-point writing |

| Printing point control | Pizeo-positioner and galvo- scanner | DMD scanner and motorised stage |

| Min. lateral step size | Continuous scanning | 120 nm |

| Min. axial step size | Continuous scanning | 270 nm |

| Voxel (lateral / axial) | 0.4 / 1.0 µm | 0.4 / 1.0 µm |

| Printing speed | 100 µm/s (PZT mode) 10 mm/s (Galvo mode) |

500 µm/s (single focus) 5 mm/s (10 foci) |

| Focus control and wave-front correction | No | Yes |

| Additional laser output port | No | Yes |

*mm: millimeter, µm: micrometer, nm: nanometer

The Digital Holography-based 3-D Nano-Builder developed by CUHK Faculty of Engineering has been honoured with the globally prestigious 2018 R&D 100 Award.

Professor Shih-Chi Chen, Department of Mechanical and Automation Engineering, Faculty of Engineering, CUHK.